Designing Efficient and Reliable Bluetooth PCB Panels for Your Projects

Designing Efficient and Reliable Bluetooth PCB Panels for Your Projects

Blog Article

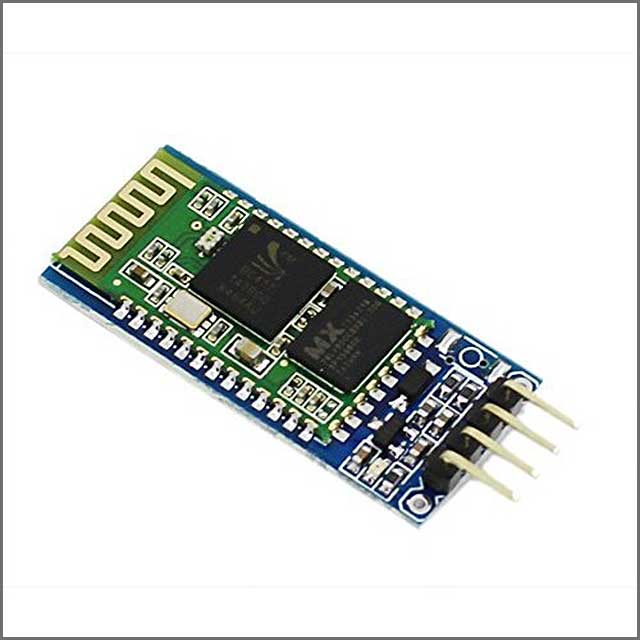

Bluetooth technology has become a critical aspect of modern connectivity, allowing products to interact wirelessly across varied industries. At the heart with this widely-used engineering lies the Bluetooth PCB panel, the engine that powers seamless communication. That blog examines the cutting-edge position of bluetooth pcb board, their significance in achieving connectivity, and the primary components that make them function.

Why Bluetooth PCB Boards Matter

Bluetooth PCB (Printed Enterprise Board) boards aid instant data transmission between devices. They form the backbone of Bluetooth-enabled techniques, from your own wireless headphones to commercial IoT (Internet of Things) equipment. Their significance is based on giving a dependable, effective program for interaction while eating little energy.

Data Encouraging Bluetooth Growth

Wireless technology is not only a feature; it's becoming a worldwide necessity. Based on the Wireless SIG Industry Outlook, Bluetooth-enabled product shipments may reach 6.4 billion annually by 2025. Among them, programs in intelligent home products, healthcare, and automotive programs are quickly expanding. Bluetooth PCB panels function being an essential enabler of the explosive growth.

Crucial The different parts of Wireless PCB Panels

To totally appreciate the role of Wireless PCB panels, it can help to comprehend their critical parts and the roles they perform:

1. Microcontroller Product (MCU)

The MCU works as mental performance of the Bluetooth PCB. It procedures information and manages transmission between devices by relaying directions to the Wireless module. High-efficiency MCUs are sought following to make sure responsiveness and low-power operation.

2. Antenna

Effective antennas are integrated for reliable connectivity. They transfer and get radio frequency signs, developing the building blocks of the board's wireless capabilities. Contemporary Wireless PCB boards frequently integrate ceramic antennas for lightweight design and high performance.

3. Wireless Module

Sitting in the centre of the table, that component determines the connection between devices. Several use modifications of Wireless Minimal Power (BLE) adventures, specifically made to cut back energy usage while ensuring strong connectivity.

4. Energy Management Enterprise

Energy performance is non-negotiable in the current connected ecosystem. These tracks guarantee the successful usage of power from the ability present, enhancing battery performance across units like wearables or medical equipment.

5. Produced Signal Layout

The look of the PCB design is pivotal. Parts should be carefully put to prevent electromagnetic interference (EMI) and to enhance the signal strength. A well-structured PCB design identifies the connectivity and efficiency of a Bluetooth device.

Operating the Future of Connectivity

The significance of Wireless PCB panels cannot be overstated in the current tech-forward world. By adding cutting-edge parts like BLE segments and effective energy management tracks, these panels are the foundations of seamless instant interaction. With the surge in intelligent units and IoT systems, enhanced PCB styles may remain needed for connectivity.

Bluetooth PCB boards continue steadily to discover possibilities across industries, providing billions of units closer together. This wave of creativity is why firms are investing heavily in improving PCB systems to make sure low power usage, robust performance, and reliable communication. Whether you are a technology fan or someone working in technology, knowledge Wireless PCB panels is fundamental to appreciating the backbone of contemporary connectivity.

Report this page